Just‑in‑Time Manufacturing: 7 Essential Steps to Effortlessly Cut Inventory Waste

Imagine walking into a warehouse full of products gathering dust. They’re unsold, unused, and slowly draining your resources. On the other end, production is delayed because materials didn’t arrive on time. This isn’t just poor planning—it’s the cost of inefficient inventory management. Many businesses struggle with either overstocking or stockouts, both of which can cripple performance.

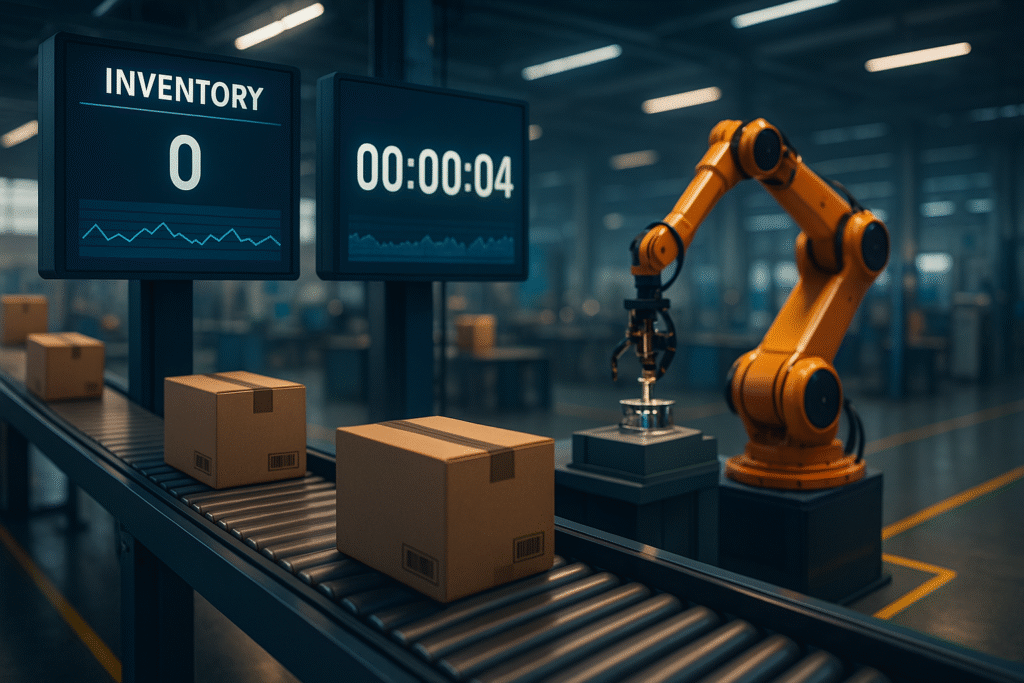

That’s where Just-in-Time (JIT) manufacturing comes in. JIT is a lean strategy focused on producing exactly what’s needed, exactly when it’s needed—no more, no less. It reduces inventory waste, improves cash flow, and ensures better alignment between production and customer demand.

What is JIT and How Does It Work?

JIT is a production methodology that aligns raw material orders from suppliers directly with production schedules. So, instead of forecasting and stockpiling, JIT companies rely on real-time demand to dictate what gets made and when. The goal: reduce waste, improve responsiveness, and optimize efficiency.

Core Principles of JIT

Some of the core principles to rely on in JIT include:

- Demand-Pull System

Production in JIT begins only after a customer order is received, not based on forecasts. As a result, it ensures that resources are used efficiently and inventory is kept to a minimum. It eliminates guesswork, prevents overproduction, and aligns manufacturing output directly with customer demand.

- Continuous Flow

JIT emphasizes the uninterrupted movement of materials and products throughout the production process. Thus, by eliminating bottlenecks and downtime, it reduces lead times and enhances responsiveness. A continuous flow ensures that every part of the system moves in sync with minimal delays.

- Zero Waste Philosophy

This principle ensures that every action in the production chain adds value. For instance, activities like excess handling, overproduction, and waiting time are minimized or eliminated. The goal is to improve efficiency, reduce costs, and focus only on processes that directly contribute to the final product.

Foundations for JIT Success

Implementing JIT requires a strategic shift in how a company views inventory, relationships, and processes. The following are essential to making it work:

- Strong Supplier Relationships

In JIT, dependable suppliers are crucial, as materials need to arrive exactly when required. This demands long-term partnerships with vendors who meet stringent delivery and quality standards. Flexibility, open communication, and mutual trust are more valuable than cost savings alone.

- Real-Time Inventory Management

Operating with lean inventory requires complete visibility into stock levels at all times. Tools such as barcodes, RFID, and automated systems help monitor usage and replenish inventory based on actual consumption. This reduces overstock, prevents shortages, and supports just-in-time delivery.

- Efficient Production Scheduling

Production plans must be closely tied to real-time customer demand. Likewise, effective scheduling ensures that machines, materials, and manpower are available exactly when needed. This reduces idle time, prevents inventory build-up, and keeps the production line moving smoothly.

- Standardized and Quality-Controlled Processes

With no excess inventory to fall back on, every production step must be consistent and error-free. That is to say, standard operating procedures (SOPs) and quality checks must be embedded at each stage. This minimizes rework and ensures stable, high-quality output.

- Technology Integration

Technology is the backbone of JIT systems. Moreover, tools like AI-based forecasting, IoT-enabled sensors, and cloud-based platforms offer real-time data and analytics. These technologies improve decision-making, allow for quick adjustments, and ensure supply chain agility.

Inventory Reduction Strategies

Here are a few strategies that work under JIT to reduce the inventory include:

- Demand-Driven Replenishment

Instead of ordering based on predictions, JIT systems reorder materials when actual usage occurs. Thus, it keeps inventory levels aligned with real-time demand. Additionally, it reduces waste, improves responsiveness, and optimizes working capital.

- Smaller, More Frequent Orders

Rather than ordering in bulk, JIT supports frequent, smaller shipments. It lowers storage costs, minimizes risk of obsolescence, and keeps inventory moving quickly through the system. It also enhances supply chain flexibility.

- Process Optimization

A streamlined process reduces the need for buffer inventory by eliminating inefficiencies. Frequent reviews, root cause analysis, and workflow improvements ensure that materials move efficiently from one stage to the next. Also, this supports lean, predictable operations.

Quality Control in JIT

With limited inventory buffers, there’s no room for errors in JIT. Quality must be built into every stage of the process:

1. Built-in Quality Checks

Quality assurance must be an ongoing part of the production process—not an afterthought. Embedding inspection points throughout the workflow helps detect and fix issues early. This reduces waste, avoids rework, and ensures consistent product quality.

2. Supplier Quality Assurance

In JIT systems, suppliers are expected to deliver error-free components. So, regular audits, consistent performance tracking, and clear quality requirements help maintain high standards. A reliable supply base ensures that incoming materials won’t cause production issues.

3. Poka-Yoke (Error-Proofing)

Poka-Yoke techniques are designed to prevent mistakes before they happen. These include physical guides, automation tools, and alerts that eliminate human error. They help maintain accuracy, reduce rework, and ensure a flawless workflow.

4. Root Cause Problem Solving

When a defect occurs, JIT requires a thorough analysis to find the root cause. Techniques like Fishbone Diagrams, Pareto Charts, and 5 Whys are used to address issues at their source. This leads to long-term process stability and continuous improvement.

Production Scheduling Techniques

Effective scheduling is critical in JIT to maintain flow and meet demand without building excess inventory:

1. Pull-Based Scheduling

JIT uses a demand-pull approach where production begins only after an actual order is placed. This prevents excess inventory and aligns output with real customer needs. It also reduces storage costs and improves manufacturing focus.

2. Heijunka (Level Loading)

Heijunka helps distribute workloads evenly over time to avoid production spikes. It smooths the flow of materials and maintains a consistent pace. This stabilizes operations and strengthens supplier relationships by creating predictable demand.

3. Kanban System

Kanban uses visual signals—like cards or digital boards—to indicate when inventory needs replenishment. Also, it supports continuous flow, reduces manual tracking, and ensures materials are restocked just in time. Kanban systems also improve communication across teams.

4. Flexible Workforce and Equipment

Flexibility allows manufacturers to adapt quickly to changes in product types or demand volumes. Cross-trained employees and multi-functional machines make it easier to shift production without delays. This adaptability is essential in dynamic market environments.

Risk Management in JIT Systems

JIT offers efficiency but comes with higher operational risk. Here’s how to prepare:

1. Diversified Supplier Base

Relying on a single supplier can jeopardize operations during disruptions. By maintaining multiple qualified vendors, businesses create redundancy and reduce dependency. This helps ensure a stable flow of materials under varying conditions.

2. Safety Stock for Critical Components

Although JIT discourages holding inventory, certain critical parts may require minimal safety stock. In addition, this small buffer protects against supply chain interruptions and ensures uninterrupted production.

3. Advanced Forecasting

AI and analytics tools help predict demand changes more accurately. Hence, this foresight allows companies to adjust orders, schedule production efficiently, and reduce the risk of shortages. Nevertheless, better forecasting supports proactive rather than reactive management.

4. Emergency Response Planning

Contingency plans are essential for JIT stability. Therefore, companies should identify backup suppliers, alternative logistics routes, and secondary production facilities. These measures help maintain operations during unexpected disruptions like natural disasters or geopolitical events.

Final Thoughts

Just-in-Time manufacturing is more than just a method—it’s a mindset. So, it demands discipline, coordination, and precision across every function. When executed well, JIT reduces waste, lowers costs, boosts quality, and improves customer responsiveness.

However, the true strength of JIT lies in its balance—between lean inventory and operational resilience, between efficiency and flexibility. With the right systems, partners, and culture in place, JIT can become a powerful driver of long-term competitive advantage.