Takt Time vs Cycle Time: Key Lean Metrics for Production Success

In Lean manufacturing, numbers tell the story of efficiency. They show whether a process is aligned with customer demand, whether a team is operating at peak productivity, and whether resources are being used effectively. Among these numbers, two stand out as fundamental: takt time and cycle time.

At first glance, they may seem similar, both measuring aspects of time within a production process. However, they answer very different questions. Takt time reflects the pace of demand, while cycle time reflects the pace of production. When both are understood and managed correctly, they become powerful tools for achieving flow, reducing waste, and meeting customer expectations consistently.

This blog will dive deep into these two Lean metrics, explain their differences, explore how they work together, and share practical strategies for applying them to real-world production challenges.

What is Takt Time?

Takt time is the rhythm of customer demand translated into production terms. The word takt comes from the German word for “baton” in music, symbolizing the beat that sets the pace for an orchestra. In manufacturing, takt time is the beat that ensures products are made at the rate customers require.

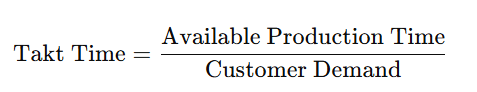

Formula:

Example:

If your factory operates for 480 minutes in a day and customers require 240 units, the takt time is 2 minutes. This means that to keep up with demand, one unit should be produced every 2 minutes.

Key Characteristics of Takt Time:

- Driven by customer demand

- Sets the maximum pace for production

- Serves as a benchmark to prevent overproduction or underproduction

In essence, takt time ensures that production matches customer needs without generating excess inventory or falling short.

What is Cycle Time?

Cycle time is the actual time it takes to complete one unit of work from start to finish. Unlike takt time, which is driven by demand, cycle time is driven by operational capability.

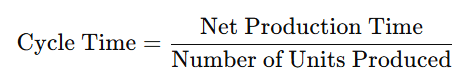

Formula:

Example:

If a workstation produces 240 units in 480 minutes, the cycle time is 2 minutes per unit.

Key Characteristics of Cycle Time:

- Measures actual process performance

- Varies based on efficiency, resources, and operator skill

- Highlights bottlenecks and improvement opportunities

Cycle time shows whether your process is efficient enough to meet takt time. If cycle time is shorter than takt time, you have capacity to spare. If it is longer, you risk failing to meet demand.

Takt Time vs. Cycle Time: The Core Difference

Although both are Lean time-based metrics, they answer different questions:

| Aspect | Takt Time | Cycle Time |

| Definition | The pace of customer demand | The pace of actual production |

| Calculation | Available time ÷ Demand | Production time ÷ Units produced |

| Focus | Customer-driven | Process-driven |

| Purpose | Align production with demand | Measure efficiency and capability |

| Interpretation | Sets the “required beat” | Shows the “current beat” |

Simply put: Takt time is what you need to achieve. Cycle time is what you are actually achieving.

Why Both Metrics Matter

Using only takt time without cycle time leaves you blind to operational capability. Using only cycle time without takt time leaves you disconnected from customer demand. Together, they form a complete picture.

- When cycle time ≤ takt time: You can meet demand, possibly with room to increase output.

- When cycle time > takt time: The process cannot keep up with demand, requiring intervention.

Balancing the two ensures that production stays synchronized with demand while maintaining efficiency.

Practical Example: Applying Takt and Cycle Time

Imagine a car assembly plant that produces vehicles for a growing market.

- Available production time: 480 minutes

- Customer demand: 120 cars per day

- Takt time = 480 ÷ 120 = 4 minutes

This means the plant should produce one car every 4 minutes.

Now, suppose the cycle times at different stations are:

- Body assembly: 3 minutes

- Paint shop: 5 minutes

- Final assembly: 4 minutes

Here, the paint shop exceeds the takt time, creating a bottleneck. Without intervention, customer demand cannot be met. Managers might respond by redistributing tasks, adding resources, or improving paint shop efficiency.

This example shows how takt and cycle time work hand in hand to reveal both expectations and reality.

Common Misunderstandings About Takt and Cycle Time

- Assuming they are interchangeable

Although both are measured in minutes per unit, takt and cycle time represent demand and capability, respectively. - Ignoring variability in cycle time

Cycle time can fluctuate due to operator skill, machine performance, or supply delays. Regular measurement is crucial. - Treating takt time as fixed

Takt time changes when demand or available time shifts. It should be recalculated whenever conditions change.

How to Use Takt and Cycle Time Together

Step 1: Calculate Takt Time

Start with customer demand and available working hours.

Step 2: Measure Cycle Time

Track actual times for each process step, preferably over several runs for accuracy.

Step 3: Compare the Two

- If cycle time < takt time, you are capable of meeting demand.

- If cycle time > takt time, improvements are required.

Step 4: Identify Gaps and Bottlenecks

Focus on the stations where cycle time exceeds takt time.

Step 5: Implement Lean Improvements

Apply methods such as workload balancing, standard work, automation, or Kaizen to align cycle time with takt time.

Lean Tools that Support Takt and Cycle Time

- Yamazumi Board

Helps visualize operator workloads and balance tasks according to takt time. - Value Stream Mapping

Shows the entire flow of materials and information, highlighting areas where cycle times misalign with takt. - Standard Work

Defines best practices for each task, reducing variation and ensuring cycle times stay consistent. - 5S and Visual Management

Organizes the workplace to minimize wasted motion and delays that inflate cycle time.

Benefits of Mastering Takt and Cycle Time

- Customer Satisfaction

Aligning with takt ensures that customer demand is met consistently and predictably. - Waste Reduction

When cycle time exceeds takt time, inefficiencies are uncovered and eliminated. - Resource Optimization

Both metrics guide better use of people, machines, and materials. - Continuous Improvement

Regular comparison of takt and cycle times drives ongoing efficiency initiatives. - Predictability in Operations

Managers can forecast outcomes more accurately and make better scheduling decisions.

Challenges in Managing Takt and Cycle Time

- Demand Fluctuations

Customer demand may rise or fall, requiring frequent recalculation of takt time. - Complex Processes

In multi-step workflows, balancing each step to match takt can be challenging. - Human Factors

Operator skill, fatigue, and engagement affect cycle time consistency. - Equipment Limitations

Machines may not always sustain the pace needed to meet takt time.

These challenges highlight the need for flexibility and continuous monitoring.

Best Practices for Success

- Recalculate Takt Regularly

Update takt whenever demand or working hours change. - Measure Cycle Time Accurately

Use time studies, digital monitoring, or sensors for precise measurement. - Balance Workloads

Distribute tasks evenly across operators or machines to keep cycle times in line with takt. - Integrate Feedback

Engage employees in improvement efforts since they often see process issues first. - Combine with Continuous Improvement Programs

Use Kaizen events or Six Sigma projects to reduce cycle time and stabilize performance.

Strategic Impact of Takt and Cycle Time

When organizations master both metrics, they move beyond firefighting and into proactive management. Instead of reacting to missed deadlines or backlogs, leaders can predict problems, adjust resources, and maintain a smooth flow that meets demand consistently.

This alignment of pace and capability builds resilience in the face of market shifts and positions companies to scale sustainably.

Final Thoughts

Takt time and cycle time are cornerstones of Lean production. One defines the rhythm of customer demand, the other reveals the true pace of operations. The balance between the two determines whether an organization delivers on promises while maximizing efficiency.

By understanding, monitoring, and continuously improving both metrics, businesses can achieve higher productivity, reduced waste, and greater customer satisfaction. In the world of Lean, success is not about speed alone, it is about harmony between what is required and what is possible.